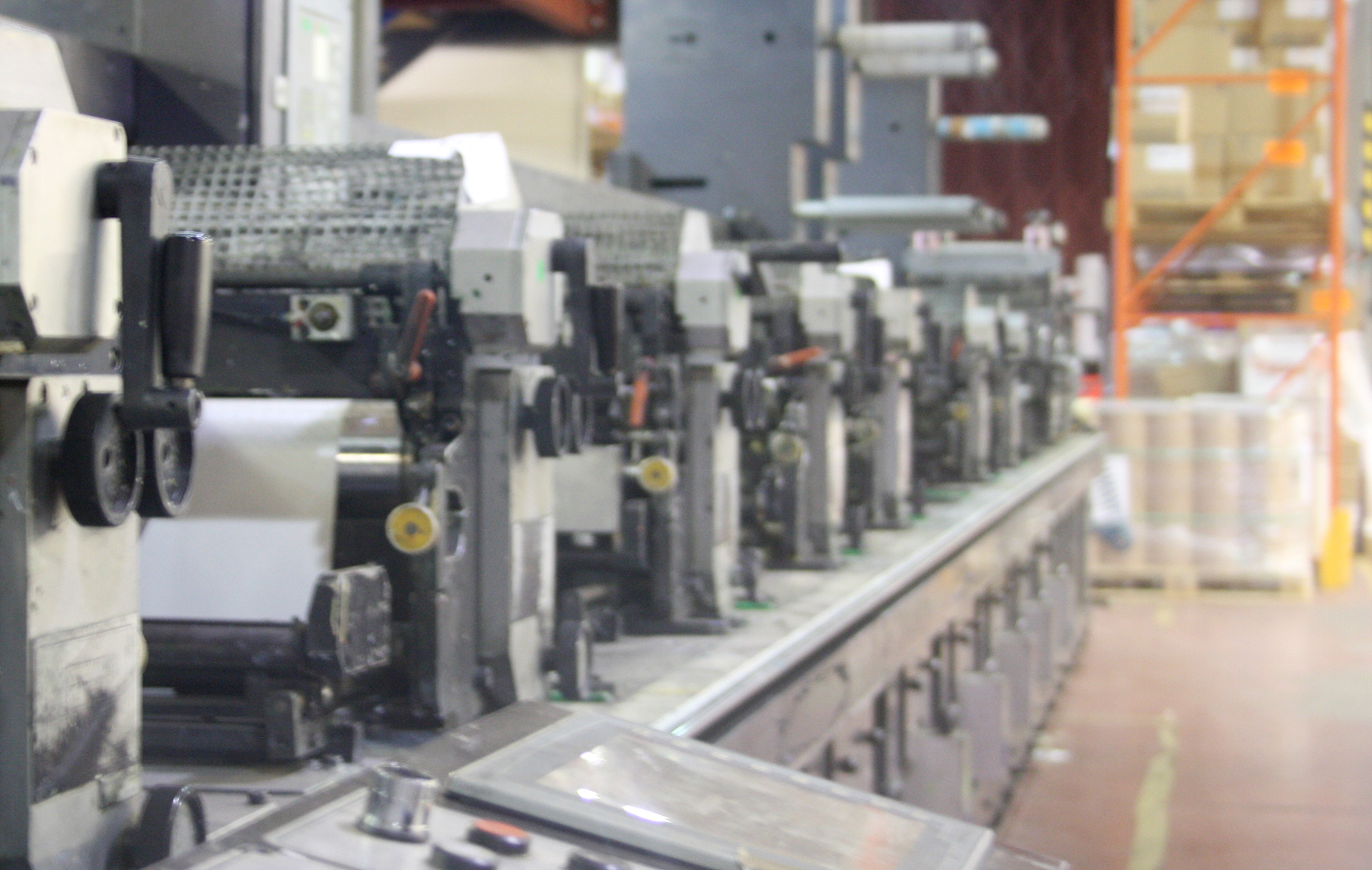

It's the question that sparks heated discussions at industry conferences: cold foiling or hot foiling? The truth is, both technologies have their place in a modern print operation, but knowing when to use each one can make the difference between profit and loss.

Let's start with the speed demon: cold foiling. Using UV-curable adhesives instead of heat and pressure, cold foiling can dramatically increase production speeds while offering the flexibility to foil over previously printed areas without registration headaches. If you're running high-volume commercial work like magazines, catalogs, or direct mail pieces, cold foiling is often your best friend.

But don't count out hot foiling just yet. When it comes to adhesion strength and working with challenging substrates like textured papers, leather goods, or premium packaging materials, hot foiling still reigns supreme. The heat and pressure create bonds that simply can't be matched by cold processes in many applications.

The numbers tell an interesting story: cold foiling typically reduces production time by 40%, while hot foiling delivers superior durability and that premium appearance that luxury brands demand. Cost analysis shows that the choice often comes down to volume, substrate, and quality requirements for each specific job.

Smart operations are investing in both technologies, treating them as complementary tools rather than competing alternatives. This approach allows for optimal method selection based on the specific requirements of each project.

The cold versus hot foiling debate misses the point entirely. The real question isn't which is better, but rather which is better for your specific application. The most successful operations master both.