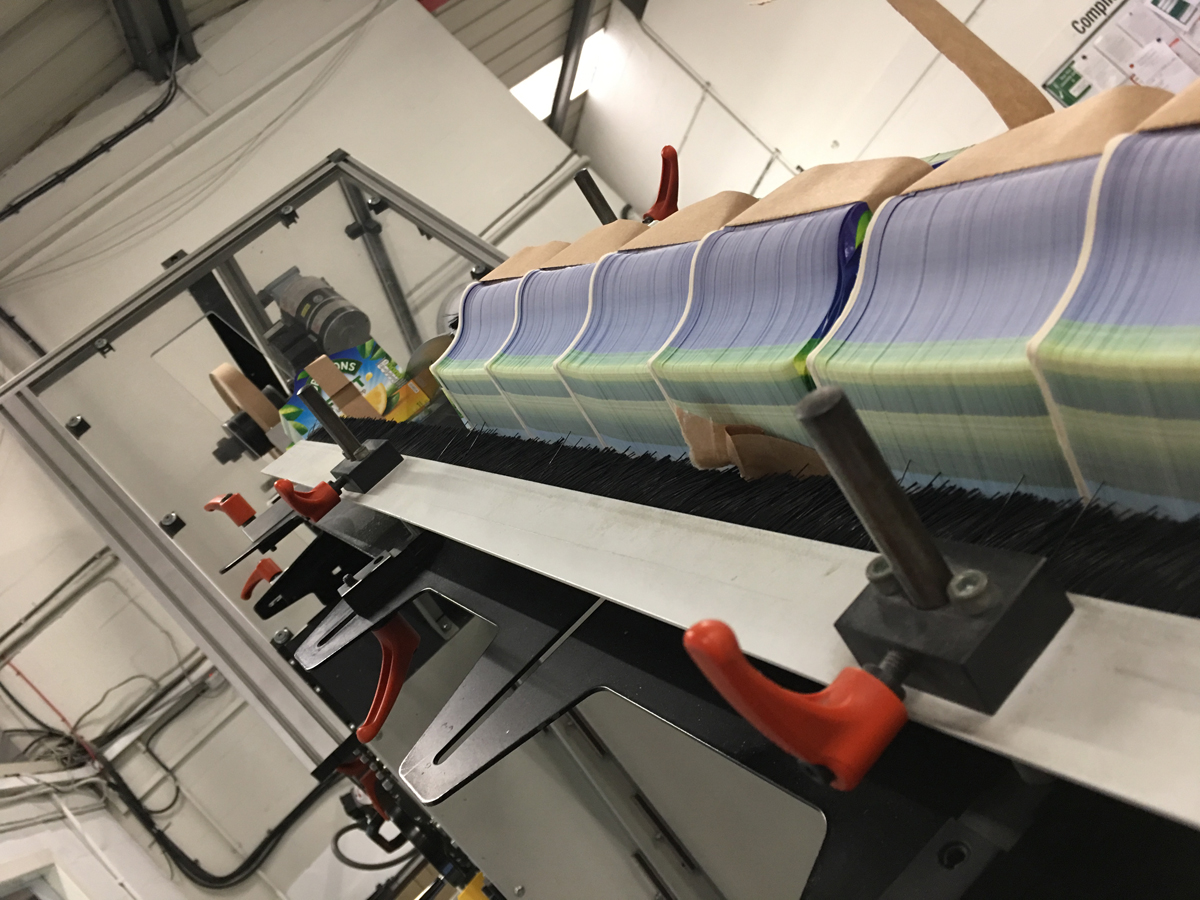

Nothing ruins a production run faster than discovering foiling defects after thousands of pieces have already been processed. If you've been there, you know the frustration – and the cost. The good news? Most foiling defects are preventable with the right knowledge and procedures.

Let's start with the big three: poor adhesion, patchy coverage, and registration problems. Poor foil adhesion usually comes down to three culprits: incorrect temperature settings, inadequate pressure, or contaminated substrates. The fix? Regular calibration schedules and proper substrate preparation protocols. It sounds basic, but these fundamentals prevent the majority of adhesion headaches.

Patchy foil coverage tells a different story – often pointing to worn dies, incorrect dwell time, or foil compatibility issues with specific substrates. The solution involves maintaining proper die condition and ensuring your foil specifications match your substrate requirements. This is where detailed record-keeping pays dividends.

Registration problems are perhaps the most frustrating because they can develop gradually throughout a run. They typically stem from substrate dimensional instability or machine alignment issues. Environmental controls and regular maintenance schedules are your best defense, but advanced monitoring systems now provide real-time feedback that allows immediate corrections.

The key to consistent quality lies in establishing comprehensive checkpoints throughout your production process. This proactive approach catches issues before they multiply and ensures every piece meets customer expectations.

Quality control in foiling isn't just about fixing problems – it's about preventing them. Invest in proper procedures and monitoring systems now, and you'll save significantly in waste, rework, and customer satisfaction down the line.